-

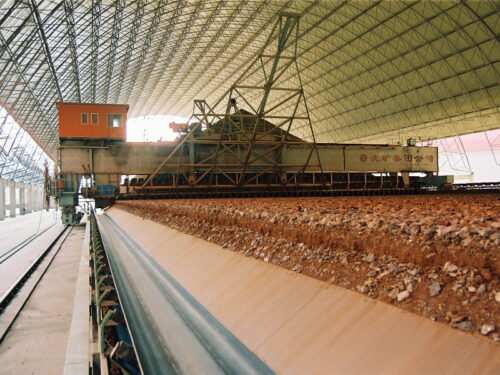

Bucket wheel stacker and reclaimers uses "bucket wheels" to remove material from the pile they are reclaiming. It be assembled differently based on the required reclaiming load rate and boom length. These changes are made in order to accommodate for the associated fluctuations in flow rates and load patterns. In the event of high material flow rates, a combination of a boom and bucket wheel is used.

Bucket wheel stacker and reclaimers uses "bucket wheels" to remove material from the pile they are reclaiming. It be assembled differently based on the required reclaiming load rate and boom length. These changes are made in order to accommodate for the associated fluctuations in flow rates and load patterns. In the event of high material flow rates, a combination of a boom and bucket wheel is used. -

A stacker has three basic movements:

A stacker has three basic movements:- Luffing: this is vertical movement, stacker uses hydraulic cylinder to control the boom conveyor up and down.

- Travelling: stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move along the stockyard as required. For this purpose, 3 in 1 (motor, gearbox, brake) driving unit are used in long traveling system of stacker.

- Slewing: this is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear.

-

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley.

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. -

The disc pelletizer is a kind of equipment for producing green pellets in pelletizing process. When the disc rotates around the central axis, the pelletized materials roll along the bottom of the disc, and the fine materials are constantly adsorbed on the wet surface of the ball, so that the ball continues to grow to the specified size.

The disc pelletizer is a kind of equipment for producing green pellets in pelletizing process. When the disc rotates around the central axis, the pelletized materials roll along the bottom of the disc, and the fine materials are constantly adsorbed on the wet surface of the ball, so that the ball continues to grow to the specified size. -

SNM has been producing various kinds of mills for more than 10 years, by taking the opportunity of national reform and opening-up policy, SNM began to cooperate with foreign famous ball mill manufacturers to produce and introduced technology, such as the United States A - C company, Foster Wheeler, MPSI company and France Stene ALSTOM.

SNM has been producing various kinds of mills for more than 10 years, by taking the opportunity of national reform and opening-up policy, SNM began to cooperate with foreign famous ball mill manufacturers to produce and introduced technology, such as the United States A - C company, Foster Wheeler, MPSI company and France Stene ALSTOM. -

Annular cooler is main equipment for the pelletizing and sintering process, it is common equipment in this industry. It is widely used for sinter and pellet cooling. There are two main functions: cooling high temperature oxidation pellet which discharged from kiln, to ensure the temperature low enough and satisfy to subsequent process; as the key point of thermal equilibrium for whole system, it recycles quantity of heat which is from high temperature pellet, and it used for previous process thereby reducing the fuel consumption.

Annular cooler is main equipment for the pelletizing and sintering process, it is common equipment in this industry. It is widely used for sinter and pellet cooling. There are two main functions: cooling high temperature oxidation pellet which discharged from kiln, to ensure the temperature low enough and satisfy to subsequent process; as the key point of thermal equilibrium for whole system, it recycles quantity of heat which is from high temperature pellet, and it used for previous process thereby reducing the fuel consumption.