-

Annular cooler is main equipment for the pelletizing and sintering process, it is common equipment in this industry. It is widely used for sinter and pellet cooling. There are two main functions: cooling high temperature oxidation pellet which discharged from kiln, to ensure the temperature low enough and satisfy to subsequent process; as the key point of thermal equilibrium for whole system, it recycles quantity of heat which is from high temperature pellet, and it used for previous process thereby reducing the fuel consumption.

Annular cooler is main equipment for the pelletizing and sintering process, it is common equipment in this industry. It is widely used for sinter and pellet cooling. There are two main functions: cooling high temperature oxidation pellet which discharged from kiln, to ensure the temperature low enough and satisfy to subsequent process; as the key point of thermal equilibrium for whole system, it recycles quantity of heat which is from high temperature pellet, and it used for previous process thereby reducing the fuel consumption. -

SNM has been producing various kinds of mills for more than 10 years, by taking the opportunity of national reform and opening-up policy, SNM began to cooperate with foreign famous ball mill manufacturers to produce and introduced technology, such as the United States A - C company, Foster Wheeler, MPSI company and France Stene ALSTOM.

SNM has been producing various kinds of mills for more than 10 years, by taking the opportunity of national reform and opening-up policy, SNM began to cooperate with foreign famous ball mill manufacturers to produce and introduced technology, such as the United States A - C company, Foster Wheeler, MPSI company and France Stene ALSTOM. -

The disc pelletizer is a kind of equipment for producing green pellets in pelletizing process. When the disc rotates around the central axis, the pelletized materials roll along the bottom of the disc, and the fine materials are constantly adsorbed on the wet surface of the ball, so that the ball continues to grow to the specified size.

The disc pelletizer is a kind of equipment for producing green pellets in pelletizing process. When the disc rotates around the central axis, the pelletized materials roll along the bottom of the disc, and the fine materials are constantly adsorbed on the wet surface of the ball, so that the ball continues to grow to the specified size. -

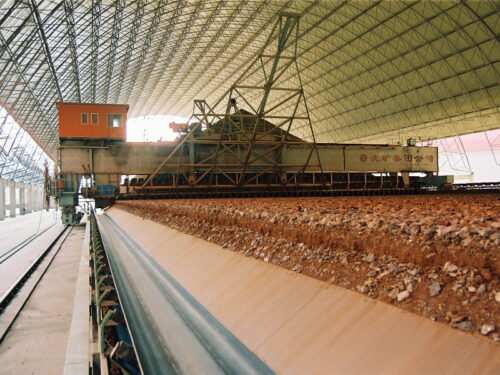

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley.

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. -

A stacker has three basic movements:

A stacker has three basic movements:- Luffing: this is vertical movement, stacker uses hydraulic cylinder to control the boom conveyor up and down.

- Travelling: stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move along the stockyard as required. For this purpose, 3 in 1 (motor, gearbox, brake) driving unit are used in long traveling system of stacker.

- Slewing: this is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear.

-

Bucket wheel stacker and reclaimers uses "bucket wheels" to remove material from the pile they are reclaiming. It be assembled differently based on the required reclaiming load rate and boom length. These changes are made in order to accommodate for the associated fluctuations in flow rates and load patterns. In the event of high material flow rates, a combination of a boom and bucket wheel is used.

Bucket wheel stacker and reclaimers uses "bucket wheels" to remove material from the pile they are reclaiming. It be assembled differently based on the required reclaiming load rate and boom length. These changes are made in order to accommodate for the associated fluctuations in flow rates and load patterns. In the event of high material flow rates, a combination of a boom and bucket wheel is used. -

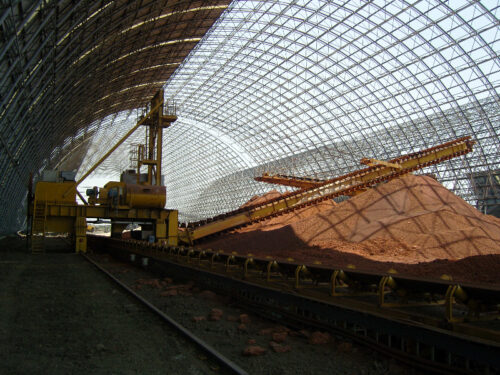

Circular Top Stacker Side Scraper Reclaimer is a machine used indoor in a circular stockyard. This machine, distinguishing itself by such features as eco-friendly performance and large storage capacity, now becomes a popular choice of applications in industries like coal mines, coal chemical sectors, iron ore mines and power plants.

Circular Top Stacker Side Scraper Reclaimer is a machine used indoor in a circular stockyard. This machine, distinguishing itself by such features as eco-friendly performance and large storage capacity, now becomes a popular choice of applications in industries like coal mines, coal chemical sectors, iron ore mines and power plants. -

Cone crusher is used in metallurgy, chemical industry, building materials, hydroelectric, road construction and other industrial sectors of different hardness of various ores or rocks for medium and fine crushing, which is characterized by advanced structure, smooth operation, high production efficiency, convenient adjustment and good granularity uniformity.

Cone crusher is used in metallurgy, chemical industry, building materials, hydroelectric, road construction and other industrial sectors of different hardness of various ores or rocks for medium and fine crushing, which is characterized by advanced structure, smooth operation, high production efficiency, convenient adjustment and good granularity uniformity. -

SNM is a professional manufacturer of design, test and fabrication of gyrator crusher with a history of more than 20years history of designing and manufacturing, the products range from PXZ 0405 to PXZ 1619. With Complete product specifications, advanced design, reliable performance, stable work, low energy consumption, the product is welcomed by users domestics and overseas.

SNM is a professional manufacturer of design, test and fabrication of gyrator crusher with a history of more than 20years history of designing and manufacturing, the products range from PXZ 0405 to PXZ 1619. With Complete product specifications, advanced design, reliable performance, stable work, low energy consumption, the product is welcomed by users domestics and overseas. -

Jaw crusher is widely used in metallurgy, mining, building materials, chemical industry, cement and other industries as one of the main equipment for crushing coarse and medium crushed ores or rocks, which has the advantages of simple structure, reliable performance, easy operation, convenient maintenance and safety service.

Jaw crusher is widely used in metallurgy, mining, building materials, chemical industry, cement and other industries as one of the main equipment for crushing coarse and medium crushed ores or rocks, which has the advantages of simple structure, reliable performance, easy operation, convenient maintenance and safety service. -

Traveling grate machine is a kind of thermal equipment working under high temperature environment, and its main parts are made of heat-resistant alloy steel. The working mode is to distribute iron pellets on slow running grate bed, use the waste heat of annular cooler and hot air flow from rotary kiln to dry, preheat, oxidize and solidify green pellets, and then directly send them to rotary kiln for roasting. The powder created in the production process of traveling grate machine is collected by ash hopper and will be reused.

Traveling grate machine is a kind of thermal equipment working under high temperature environment, and its main parts are made of heat-resistant alloy steel. The working mode is to distribute iron pellets on slow running grate bed, use the waste heat of annular cooler and hot air flow from rotary kiln to dry, preheat, oxidize and solidify green pellets, and then directly send them to rotary kiln for roasting. The powder created in the production process of traveling grate machine is collected by ash hopper and will be reused. -

Vertical Roller Mill is high efficiency widely used for high efficient energy saving grinding equipments in variety of fields, such as: cement industrialized raw and clinker material production, slag, ore, silicon, carbide slag and coal gangue grinding, and coal, chemical, power plant desulphurization.

Vertical Roller Mill is high efficiency widely used for high efficient energy saving grinding equipments in variety of fields, such as: cement industrialized raw and clinker material production, slag, ore, silicon, carbide slag and coal gangue grinding, and coal, chemical, power plant desulphurization. -

Integer tristique dictum sapien et lacinia. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Sed sed imperdiet magna, at rhoncus arcu. Cras tincidunt felis eu vehicula consequat. Proin vel gravida quam. In tincidunt aliquam nisl. Sed velit erat, aliquam sit amet metus eget, molestie auctor nulla.

Integer tristique dictum sapien et lacinia. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Sed sed imperdiet magna, at rhoncus arcu. Cras tincidunt felis eu vehicula consequat. Proin vel gravida quam. In tincidunt aliquam nisl. Sed velit erat, aliquam sit amet metus eget, molestie auctor nulla.- Premium Cotton Jersey Construction

- Embroidered Trefoil Logo at Chest

- High Stance Collar

- Full Zip with Branded Contrast Zip Pull

- Kangaroo Pockets

- Adjustable Hood

- Style Code: G84717