-

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley.

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. -

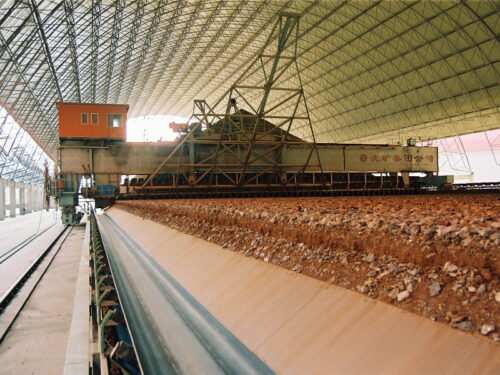

A stacker has three basic movements:

A stacker has three basic movements:- Luffing: this is vertical movement, stacker uses hydraulic cylinder to control the boom conveyor up and down.

- Travelling: stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move along the stockyard as required. For this purpose, 3 in 1 (motor, gearbox, brake) driving unit are used in long traveling system of stacker.

- Slewing: this is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear.

-

Vertical Roller Mill is high efficiency widely used for high efficient energy saving grinding equipments in variety of fields, such as: cement industrialized raw and clinker material production, slag, ore, silicon, carbide slag and coal gangue grinding, and coal, chemical, power plant desulphurization.

Vertical Roller Mill is high efficiency widely used for high efficient energy saving grinding equipments in variety of fields, such as: cement industrialized raw and clinker material production, slag, ore, silicon, carbide slag and coal gangue grinding, and coal, chemical, power plant desulphurization.