1. Working Conditions

Max absolute temperature:+42℃

Minimal absolute temperature:-25℃

Wind speed:125km/h

Max precipitation per year:350.5mm

Max precipitation per month:118mm

Max precipitation per day:80mm

Max precipitation per 30 minutes:38.7mm

Wind load:0-10m 75kg/㎡

10-20m 100kg/㎡

20-30m 135kg/㎡

Annual working days per year: 365

Annual operating days per year: 320

Work shift:3

Working hours per day:8

Operating hours per year:7680

Material Character

Dry Basis:180 t/d

Feeding Concentration:1.9%

Underflow Concentration:Rated 45%

Design 60%

2. Equipment data:

Feed slurry type and volume: top feed, 136.3 t/h

Overflow rate:130.5 t/h

Underflow rate:5.8 t/h

Specific gravity of solids:5g/cm³

Solid settling velocity: 1.2mm/s (reference value)

This data related with dust performance and feeding concentration ratio. Definitely it should be strictly decided by test.

Particle size distribution of solid:

Size:

µm % passing

166 100

74 99.7

52 93.8

37 79.8

10 36.7

D80 37

D50 17

Material of thickener: reinforced concrete.

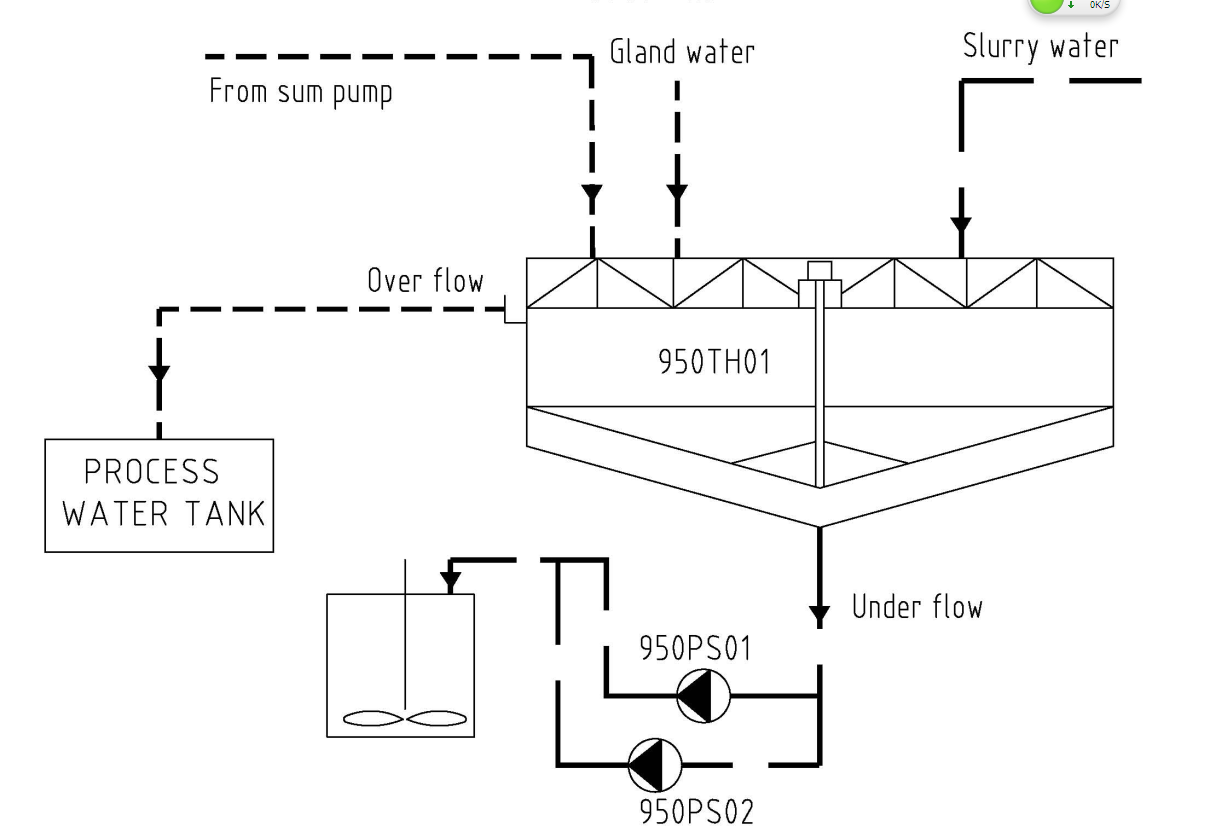

Thickener process description: thickener takes the slurry from dedusting and cleaning, through depositing, fed into mixer for recycling after treatment. Overflow goes into dedusting system, mixer does dedusting’s dust.

Schematic Drawing of Thickener

3. Equipment Description:

NZ series thickener is a kind of high efficient, intelligent thicken equipment that designed by our company together with other related domestic design institute. The thickener is able to lift rake in both manual and auto mode.

This equipment is used in separating solid and liquid mixture, which is widely used in various kindly ore beneficiation plant, coal washing plant and other fields that required separating solid and liquid material. With the advantage of the reasonable structure, advanced technology and reliable quality, the equipment is used in many industry projects.

Principle of operation:

The mixture material is coming into thickener’s flow steady drum from the pipeline located above the equipment, after the impacting treatment of the flow, the bigger size solid material will sink to bottom sinking area accumulated in cone pit, other fine size material will go to pool center for sedimentation through distribution pipeline, sinking in center area of the pool. After sinking treatment, the scraper will take the sinking material to discharge opening and discharged by bottom flow pump.

Main function for each component and characteristic:

The main structure of thickener:

- Drive unit

- Lifting structure

- Flow stable drum

- Bridge truss

- Rake frame assembly

- Electrical control system

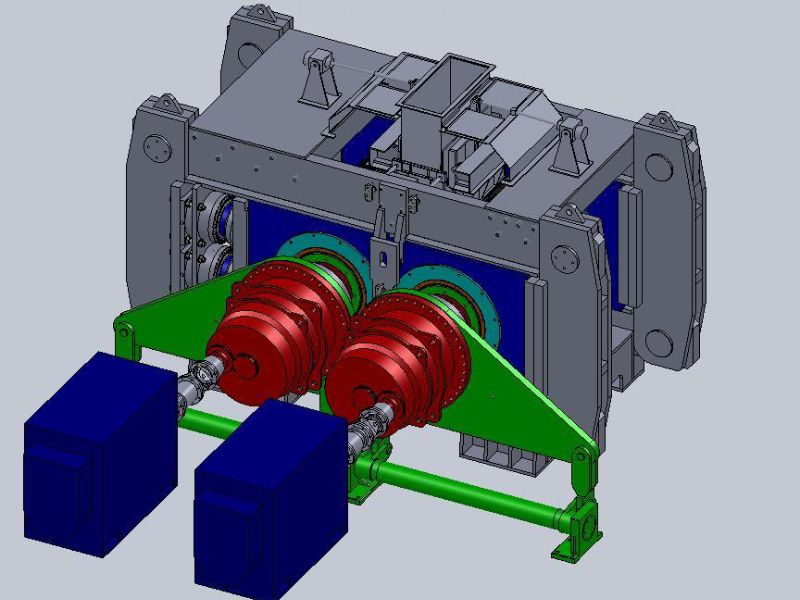

3.1 Driving device:

The drive unit is of centralized kind. The driving system used turbine worm reducer, connected with gearbox directly, transmission shaft gear joggle with warm teeth, worm pole and turbine gear teeth joggle together driving the scraper rake rotating. Driven unit is the out teeth of turbine; the equipment is safe and reliable during operation.

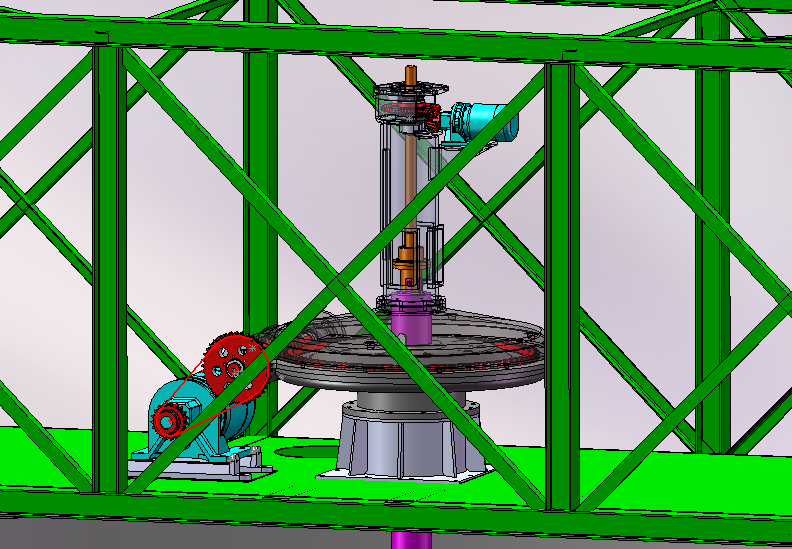

3.2 Rake lifting system.

Center rake lifting system is of screw rake lifting kind. The rake can be lifted up with load. Both auto and manual mode are available in rake lifting, which can be freely controlled as per requirement. Under auto rake lifting mode, the lifting distance and lifting action (scale on rake) can be automatically controlled to satisfy the requirement of production.

Special note, in order to guarantee the continuous safe running of the equipment, emergency overload auto rake lifting device is equipped. Working principle are as follows:

- This equipment is in the worm gear and worm reducer worm shaft head is equipped with a pressure sensor devices.

- When the concentration increased pool of sedimentary materials, scraping the clay working resistance increases, the pressure in the worm will increase, produce a axial force make the automatic control system by monitoring the pressure in the pressure sensor value to determine the size of the equipment by torque.

- When pressure exceeds the set value, pressure sensor, the elevator system control valve open, screw hoist start work improve rake plane overall rise, effectively avoid pressure rake thickener appear phenomenon.

- If the pressure is always more than the set value, carry scraper device will continue to improve, until when the driving pressure exceeds rating, thickener, automatic stop, signal alarm, not because of too much sediment pressure rake damage the equipment.

- When the pressure is less than the set value, carry scraper device automatically drops, back to normal working position.

- Better adapt to the process parameters and the volatility, the rate of ensure thickener in bad environment, large quantity stability under the condition of continuous work.

(a)when the mud scraper load > pressure sensor value (value according to the size of the process need to be sure) :

(1) the rake body ascension, through to the yellow warning light and alarm bell rang, stop rotating mud scraper, rake institutions ascension a certain height, if the load is reduced and returned to normal, the trailing stop, mud scraper start rotating, alarm to stop.

(2) if the load is constant, repeat. 1 item. When ascending a certain height, turn on the red warning light and alarm bell rang, at this time should reduce or stop the feeding system, if the load is still the same, then repeat. 1 item. To run into ascension limit switch, full stop.

(b) mud scraper load pressure sensor value (value according to the size of the process need to be sure) :

(1) rake fall start, mud scraper continues to rotate, mention rake = fell to load pressure sensor setting, rake drop stop, mud scraper continue to rotate.

(2) if the load continues to < pressure sensor Settings, repeat. 3. Until met down limit switch. Mention rake drop stop, mud scraper continue to rotate.

The device is to make full play of thickener in dynamic mechanical properties of the equipment. Ensure the reliable operation of the mechanical.

Note:

(1) when the equipment failure after parking, no compulsory starts, must find out the cause of the problem, and ruled out, can drive to continue running.

(2) when the field work to rake the limit of the pressure sensor indicated value should be adjusted according to actual working condition.

Drive and Lifting Device Sketch

And according to the actual application needs, our company carry scraper device can also switch between automatic and manual, namely the unexpected emergency alarm condition, after being forced to stop can use manual lift rake, for equipment maintenance, can also be manually will rake back to normal working condition.

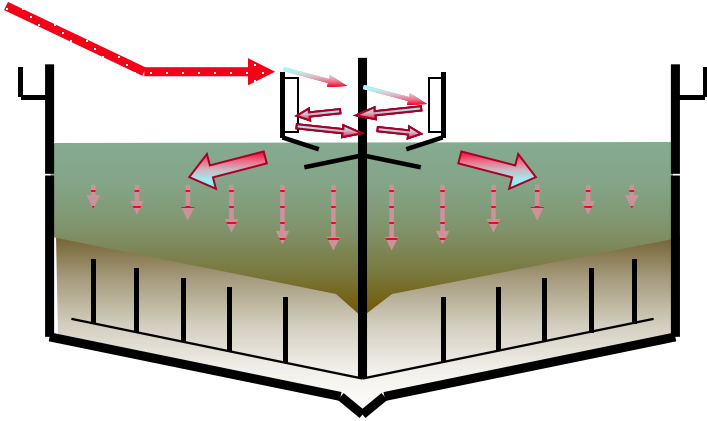

3.3 The Steady Flow Barrel

Tangent feeding into the feeding tube from the thickener overflow dam under (liquid level) into the steady flow barrels, pulp along the circular steady flow barrel wall inside the tangent movement, this design shortens the time of the settlement of solid particle path and efficient.

Again due to the fluid in steady flow cross section on sudden increase, greatly reduce the flow of fluid lost momentum, basically, containing solid particles to realize steady flow.

Tangent movement, forms certain eddy current in steady flow barrels, material under the action of centrifugal force, the larger particles along the barrel wall as a circular motion, and gradually decline, the steady flow movement surrounding the barrels, tiny particles by the center area of settling down, when they arrive in steady flow after the bucket bottom larger particles under the action of gravity settlement, to the thick bottom radiation on central upward diffusion played a small material.

Prevent superfine material along with the rising water directly into the overflow weir. Thus realized the uniform fabrics. And for the material that has been settling to the bottom layer do not impact, to ensure the stability of the underflow concentration.

The specific process as shown in the figure below:

3.4 Cable Tray

The cable tray is truss type, which function is to transfer force of scrape putty. This cable tray bear the whole weight of equipment, and let drive unit and rake frame hang in its center, and at the same time transfer the torque to pool wall (the base).

3.5 Electrical Control System

The core of center drive auto/manual up and down rake electrical control system is PLC programmable logical controller. The PLC is SIMENS brand, the advantages is fast running speed, good anti-disturbance capacity, the basic function of system control would be stored in program storage way, and two working types: hand and automatic.

Manual working mode: thickener’s running、stop 、rake up、rake down etc movement would be via the buttons, the change switch and manual control.

Automatic Manner: Adopt Pressure sensor, detecting working pressure in real time. Convert the pressure value into control signal and distribute to PLC separately so that automatically control the equipment traveling or lifting by customer program.

The electric components are products of famous imported or joint venture suppliers, reliable operation.

3.6 Rake Frame Assembly

Rake frame assembly for the steel structure truss form, through the strength of structure calculation can reach the requirement, and have higher safety coefficient, in order to ensure the equipment overload, temporary parking occurs, such as the overall security of the rake plane.

Rake in aircraft assembly equipped with vice rake to scrape set bottom flow row ore mouth materials piled up. Thickener rake tine material is 16 Mn in aircraft assembly, this material has high wear resistance, greatly improving the service life of the tine.