China is a developing country with the fastest development in the last ten or twenty years. The first generation spring cone crusher and the second generation hydraulic cone crusher are both used. However, in recent years, imported and foreign-invested hydraulic cone crushers continue to occupy the market and have the momentum of gradually replacing the first generation of spring cone crushers.

The first imported single cylinder hydraulic cone crusher was introduced from Sweden in the early 1980s and installed in Tongling Fenghuangshan copper mine. In the late 1980s, allis-Chalmers 84 Yingshi single cylinder hydraulic cone crusher was introduced from the United States and installed in Anshan East Anshan Iron Mine and Dexing Sizhou concentrator.

H-series single cylinder hydraulic cone crushers are widely used in Angang mining company, Benxi Nanfen concentrator, Jinchuan, Dexing, apple aluminum, luoaluminum group, Lala copper mine, Panzhihua Midi Concentrator, Meishan Iron Mine and other mines, while GP series single cylinder hydraulic cone crushers are widely used and promoted in small and medium-sized mines. At present, 400 sets have been installed in China.

The first batch of imported HP series multi cylinder hydraulic cone crushers were introduced from France in the mid-1990s and installed in the Three Gorges Dam project to produce sand and stone for the construction of the dam. The crushers used in the sand and gravel system of the Three Gorges dam are all from meizhuo mining machine.

The high performance and high reliability of the thousand crushers have laid the foundation for the completion of the dam construction task of the Three Gorges Dam one year ahead of schedule in ten years. The first batch installed in the iron mine

HP series multi cylinder hydraulic cone crusher is installed in Anshan Diaojuntai concentrator. The first HP series multi cylinder hydraulic cone crusher installed in nonferrous metal mine is installed in Paishanlou gold mine, creating a successful example of multi crushing and less grinding process.

HP series multi cylinder hydraulic cone crushers are used in Angang, TISCO, Maanshan Iron and steel, WISCO, Laigang, Tangshan Iron and steel, Wuyang mining, Yunnan copper, Ruida aluminum mine, Fengyuan aluminum mine, Fankou Lead zinc mine, Xitieshan lead zinc mine, Changba lead zinc mine, Lingnan gold mine and Yingezhuang Gold Mine.

Multi cylinder hydraulic cone crusher has been widely used and popularized in medium and large mines. At present, 150 sets have been installed in China.

From the perspective of the hydraulic cone crusher installed and used, the single cylinder hydraulic cone crusher has the advantages of large throughput in crushing soft ore and weathered ore, while the multi cylinder hydraulic cone crusher performs better in crushing medium hard ore and high hard ore. In terms of the reliability of crushing equipment, multi cylinder hydraulic cone crusher is more reliable than single cylinder hydraulic cone crusher, and it is not easy to crack large parts.

In the maintenance of crushing equipment, the multi cylinder hydraulic cone crusher is driven by thousands of hydraulic motors, which is simple and easy, more labor-saving and time-saving. Next, a certain amount of comparison is made between H series single cylinder hydraulic cone crusher and HP series multi cylinder hydraulic cone crusher in the application of medium and hard ores.

A. Medium Size Hydraulic Cone Crusher

The main shaft fixed hydraulic cone crusher and the main shaft floating hydraulic cone crusher are used in the crushing operation in the iron mines of Anshan Qidashan Iron Mine and TISCO.

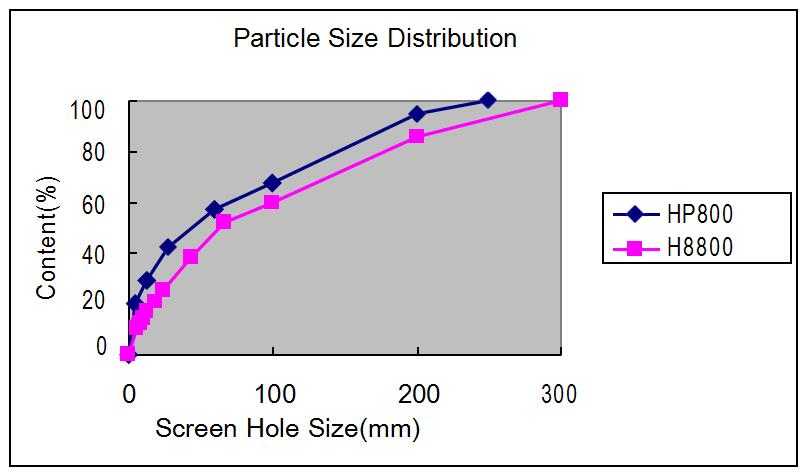

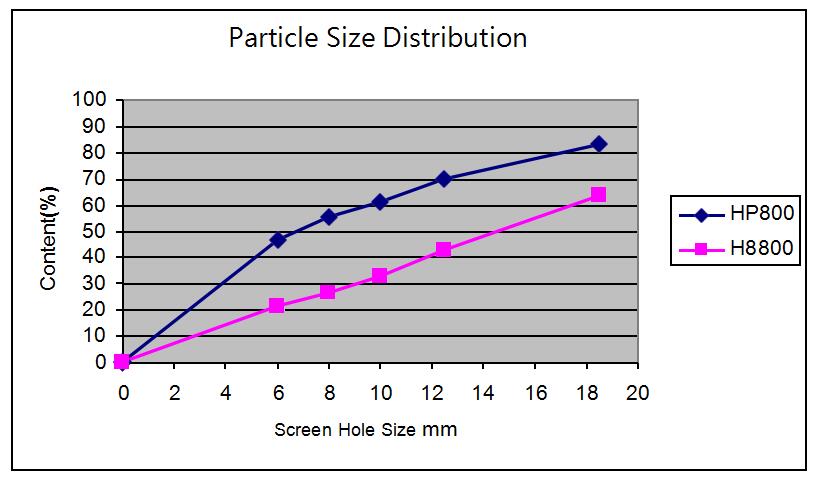

Figure 1 and 2 respectively show the feeding and discharging particle size distribution curves of HP800 and H8800 hydraulic cone crushers in the crushing operation of the same type of iron mine. The processing capacity of HP800 and H8800 corresponding to the feeding and discharging particle size distribution curves of Figure 1 and Figure 2 are 1375 tph and 1205 tph.

Figure. 1 Feed particle size distribution curve of hydraulic cone crusher in crushing operation of an iron mine

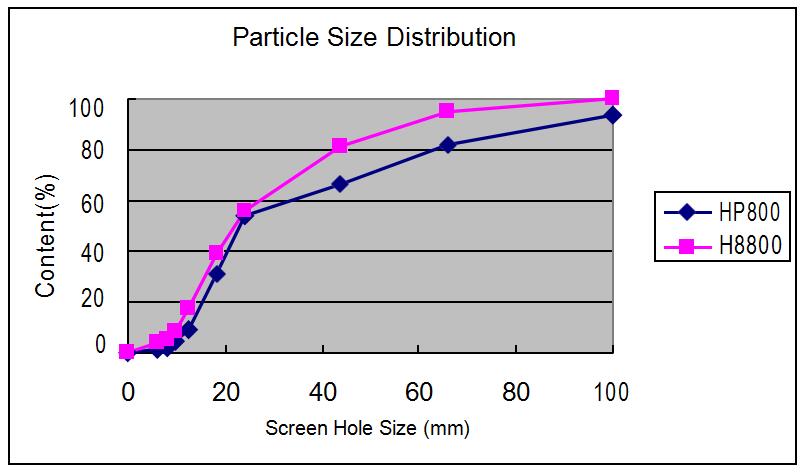

Figure 2 Discharge particle size distribution curve of hydraulic cone crusher in crushing operation of an iron mine

It can be seen from Figure 1 that the feed particle size of HP800 medium crushing cone crusher is slightly finer than that of H8800, but from Figure 2, we find that the content of fine particle in HP800 discharge is significantly higher than that of H8800.

Considering the different feeding fineness, it is not complete to evaluate the advantages and disadvantages of the crusher in medium crushing only by the discharge fineness and processing capacity. Next, we take the particle size of small 60 mm medium crushing as the target product to calculate the production capacity of HP800 and H8800 when the particle size of small 60 mm is newly generated:

HP800:1205 tph X(94.625%-57.4%)=448.6 tph

H8800:1370 tph X(70.4%-46.89%)=322.1 tph

According to the calculated data, it is not difficult to find that the production capacity of HP800 is 39.3% higher than H8800 in the newly generated particle size of 60 mm. In addition, 5% of H8800 contains 100 mm ore blocks, which will adversely affect the fine crushing operation.

B. Fine Crushing Hydraulic Cone Crusher

Main shaft fixed hydraulic cone crusher and main shaft floating hydraulic cone crusher are also used in many iron ore fine crushing operations.

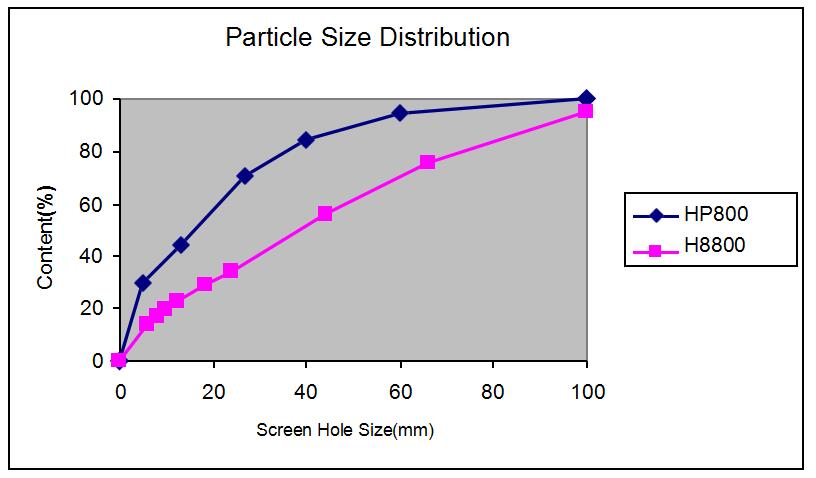

Figure 1 and Figure 4 respectively show the feeding and discharging particle size distribution curves of HP800 and H8800 hydraulic cone crushers in the same type of iron ore fine crushing operation. The processing capacity of HP800 and H8800 corresponding to the feeding and discharging particle size distribution curves in Figure 3 and Figure 4 is 575 tph and 730 tph respectively.

Figure 3 Feed particle size distribution curve of hydraulic cone crusher in fine crushing operation of an iron mine

It can be seen from Figure 3 that the feed particle size of HP800 fine crushing cone crusher is slightly thicker than that of H8800, but from Figure 4, we find that the content of finer particles in the discharge of HP800 is much higher than that of H8800.

Since the feeding fineness is different, it is incomplete to evaluate the fineness of the crusher only by the discharge fineness and processing capacity. Next, we take the particle size of 12.5mm as the target product to calculate the production capacity of HP800 and H8800 when the particle size of 12.5mm is newly generated:

HP800:575 tph x (69.85%-12.5%)=329.7 tph

H8800:730 tph x (42.61%-12.26%)=221.6 tph

According to the above calculation data, it is not difficult to find that the fine crushing HP800 hydraulic cone crusher is 48.8% larger than the fine crushing H8800 hydraulic cone crusher in the production capacity of the newly generated 12.5mm particle size.

Fine crushing HP800 and H8800 youqiandu are newly installed hydraulic cone crushers in recent two or three years. They are equipped with good automatic control devices, which basically represent the most advanced level of hydraulic cone crushers in the contemporary world.

In the fine crushing operation of Anshan Qidashan concentrator, Panzhihua Midi Concentrator H8800, luolvqun H6800 and H7800, Angang Gongchangling iron mine, Hujiamiao iron mine and other mines, the discharge fineness can only reach about 40% small thousand 12mm, Dagushan Iron Mine and Jinchuan bare ore are relatively soft, and the discharge fineness can reach about 50% small thousand 12mm. Dexing Dashan Concentrator has soft ore hardness and the best discharge fineness, which can reach about 57% small 1000 12mm, but the 1000 load is too heavy and the frame cracks 3 times.

Figure 4 Discharge particle size distribution curve of hydraulic cone crusher in fine crushing operation of an iron mine

From the fine crushing cases of ores with medium hardness and above, under the same specifications of single cylinder hydraulic cone crusher and multi cylinder hydraulic cone crusher, multi cylinder hydraulic cone crusher can produce more qualified products. Generally speaking, the harder the hardness is, the greater the difference is.

C. Successful Application of Hydraulic Cone Crusher In The Process of More Crushing And Less Grinding

The multi cylinder hydraulic cone crusher has the advantages of fine particle size and low circulating load. It can increase production and efficiency in old mines. Using the original crushing and screening system, it can only transform the crusher to realize more crushing and less grinding. At the same time, it also shows outstanding advantages in improving the output of crushing and grinding system.

Pyd1650 is selected in the fine crushing design of Paishanlou gold mine in Fuxin, Liaoning Province. It is difficult to make the particle size of crushing products meet the design requirements, and the screen hole has to be placed.

Up to 15x30mm, which seriously restricts the processing capacity of the concentrator. At the end of 1998, the multi cylinder hydraulic cone crusher produced by Metso mining machinery was introduced and installed.

HP300。 After the transformation, the size of the screen hole is reduced to 10X14MM, and the content of 0 ~ 5mm in the crushed products is up to ~ 60%. In this way, the grinding capacity is increased from 1150 Tun to 1500 Tun per day, and the output is increased by 30 4%。 At the same time, the steel consumption of ore grinding in concentrator Tun decreased from 1.53 kg to 1.1 kg

The power consumption of comprehensive Tun ore decreased from 41.57 degrees to 29.2 degrees.

Chengchao Iron Mine in Wugang’s Wutuan group has been expanded from 2 million tuns to 3 million tuns per year. Three multi cylinder hydraulic crushers HP500 produced by meizhuo mining machine have been introduced and installed to replace the PYD and PyB 2100 crushers in the original process, reducing the grinding particle size from 95% to 13 mm.

The crushing and grinding capacity will be expanded to 3 million Tun per year without increasing the main grinding equipment.

The crushing process before the transformation of Dahongshan Copper Mine is three-stage and one closed circuit. Pxz-900 / 130-a hydraulic rotary crusher is selected for coarse crushing, pyb-2200 standard cone crusher is selected for medium crushing, two pyd-2200 short head cone crushers are selected for fine crushing, and three yah2460 single-layer circular vibrating screens are selected for closed-circuit inspection and screening, with screen hole size of 16 ~ 18x40mm and rectangular screen hole.

The crushing process after the transformation of Dahongshan Copper Mine is three-stage and one closed circuit. Pxz-900 / 130-a hydraulic rotary crusher is selected for coarse crushing, HP500 STD C standard cone crusher is selected for medium crushing, two HP500 sh C short head cone crushers are selected for fine crushing, and three yah2460 double-layer circular vibrating screens are selected for closed-circuit inspection and screening. The upper screen size is 25x45mm and the lower screen size is 12x45mm, Rectangular mesh.

The processing capacity of the crushing and grinding system before the transformation of Dahongshan Copper Mine is 6000 ~ 7000 tons per day, and the processing capacity of the crushing and grinding system after the transformation exceeds 10000 tons per day.