Bulk Material Handling

Contiuously transportation, stacking, reclaiming, storage and blending of bulk material

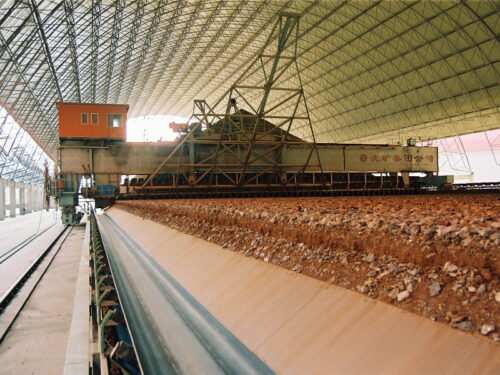

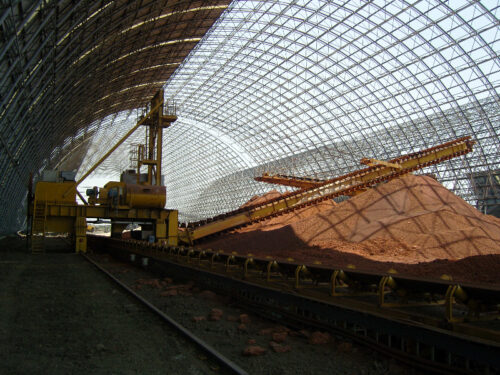

Stockyard Design

.

.

In a typical bulk material handling system, raw materials are received from trucks, ships or trains. Then they are unloaded to a yard or storage facility, often using a conveyor system. The materials are usually stored in stockpiles.

Belt conveyors are the backbone of bulk material handling systems in many different processing plants. Other equipments used in material handling systems includes stacker/reclaimer, hoppers, chutes, apron feeders, excavators, spreaders etc.

Our bulk material handling system solutions cover all scope of work as below:

(1) System process design:

- Technological process

- General layout

- General layout Road

- Equipment selection and layout

- Entrustment and coordination of other disciplines

(2) Civil engineering discipline (concrete structure, steel structure)

- Architecture: workshop, central control room, etc;

- Steel structure discipline: machine room, corridor, silo, etc;

- Equipment foundation.

(3) Electrical system

- Power supply, distribution and transformation

- Automatic control and instrumentation: centralized control system

- Communication

- Lighting

- Industrial TV monitoring: CCTV

- Grounding protection and lightning protection: electrical equipment and buildings

(4) HVAC specialty

- Ventilation, heating and air conditioning

- Dust prevention and dust removal Specialty: dry and wet

(5) Water supply and drainage discipline

- Production and domestic water supply

- Discharge and treatment of sewage and rainwater

(6) Fire fighting and fire prevention

(7) Project budget estimation

(8) Engineering Management

Related Products

Check main equipments of bulk material handling system

WE WILL REVERT BACK TO YOU IN 24 HOURS

FOLLOW US IN OUR SOCIAL NETWORKS