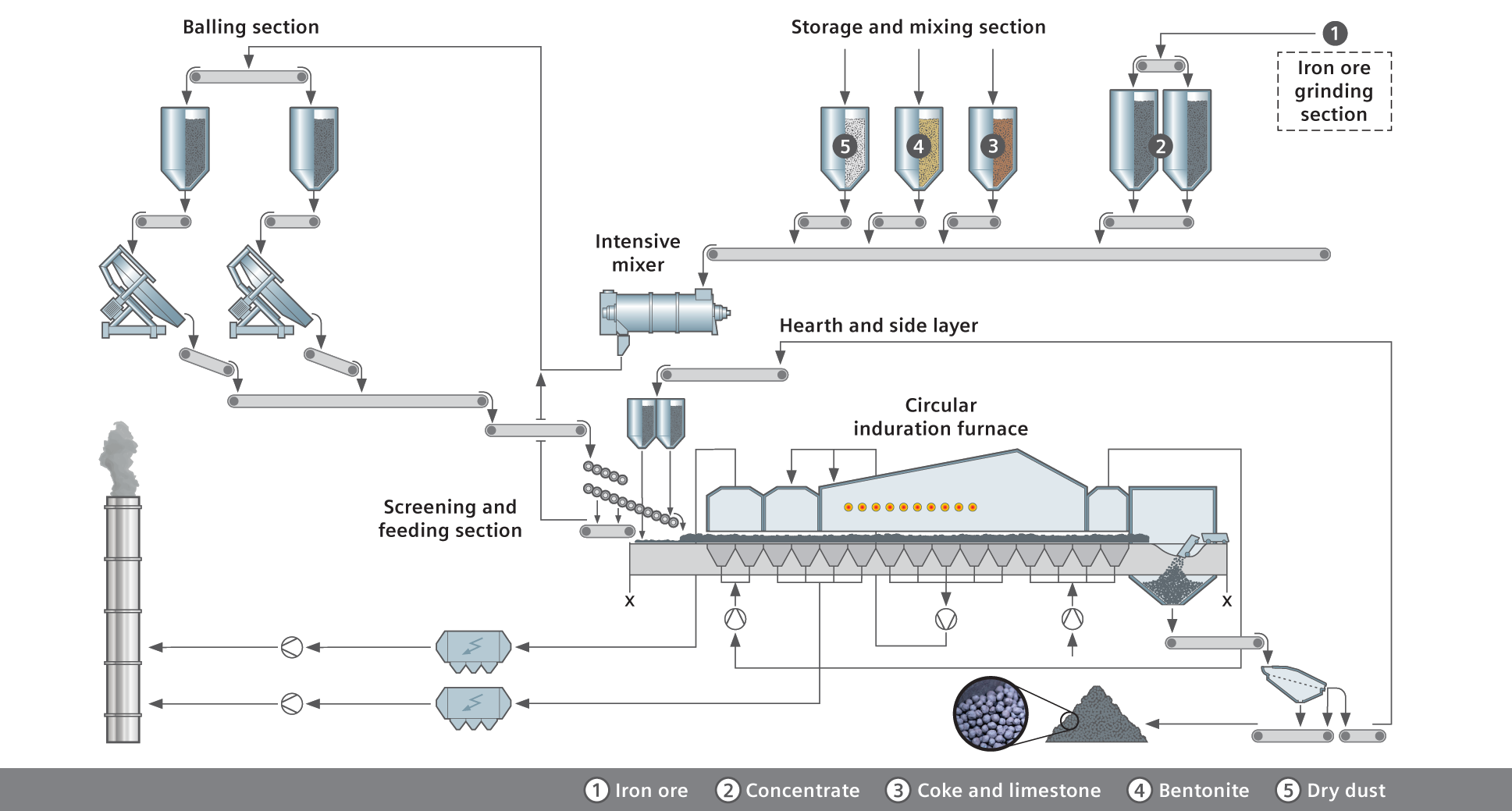

Typical Flow Sheet of a Pelletizing Plant

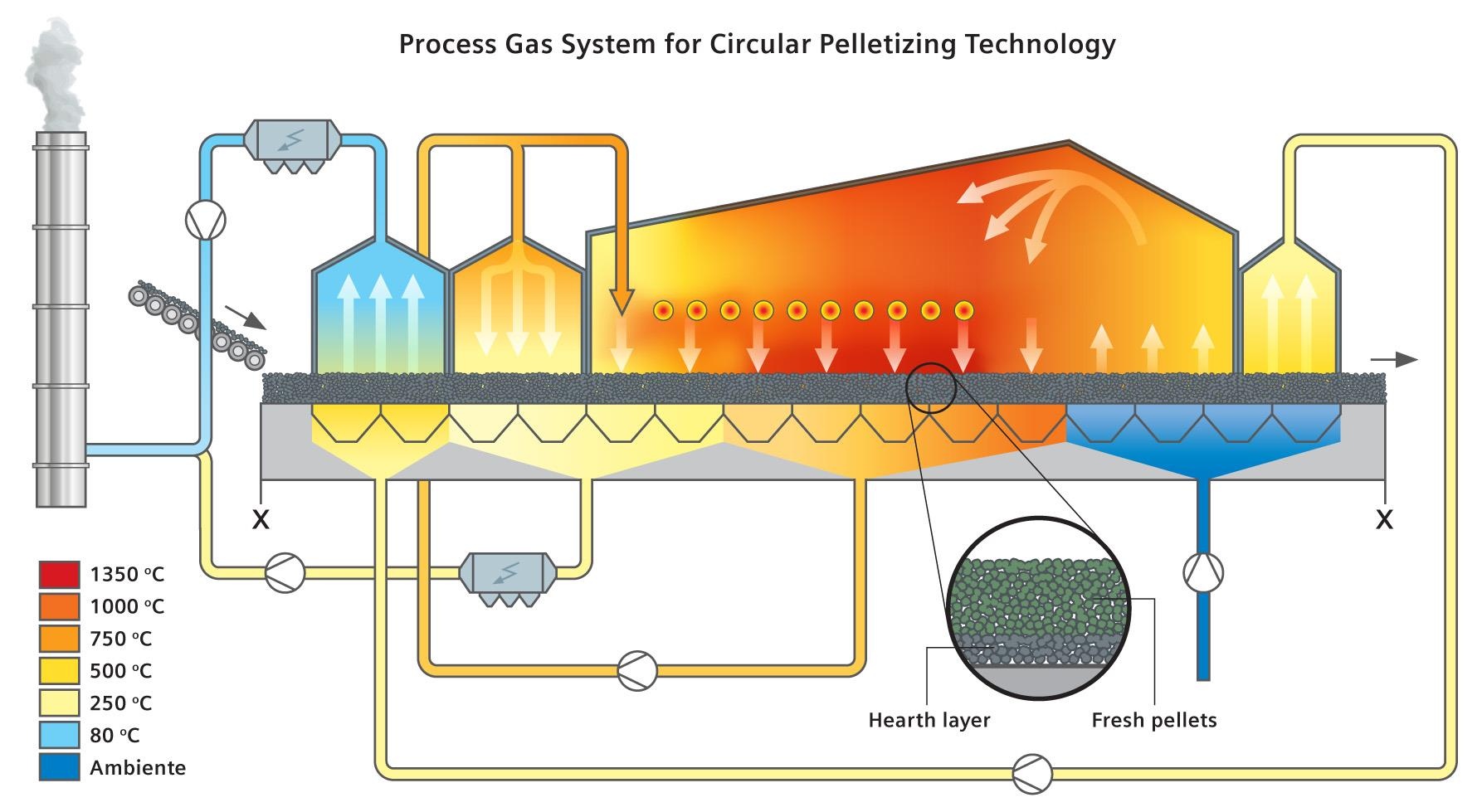

Circular Pelletizing Technology

Comparison Of Different Pelletizing Plant

Type of Plant

Capacity Range

Technical Highlights

Straight grate pelletizing plants

1 – 6 Mt/year

pelletizing plants

- Low space requirement

- Low weight = low CAPEX

- Direct firing = low fuel consumption

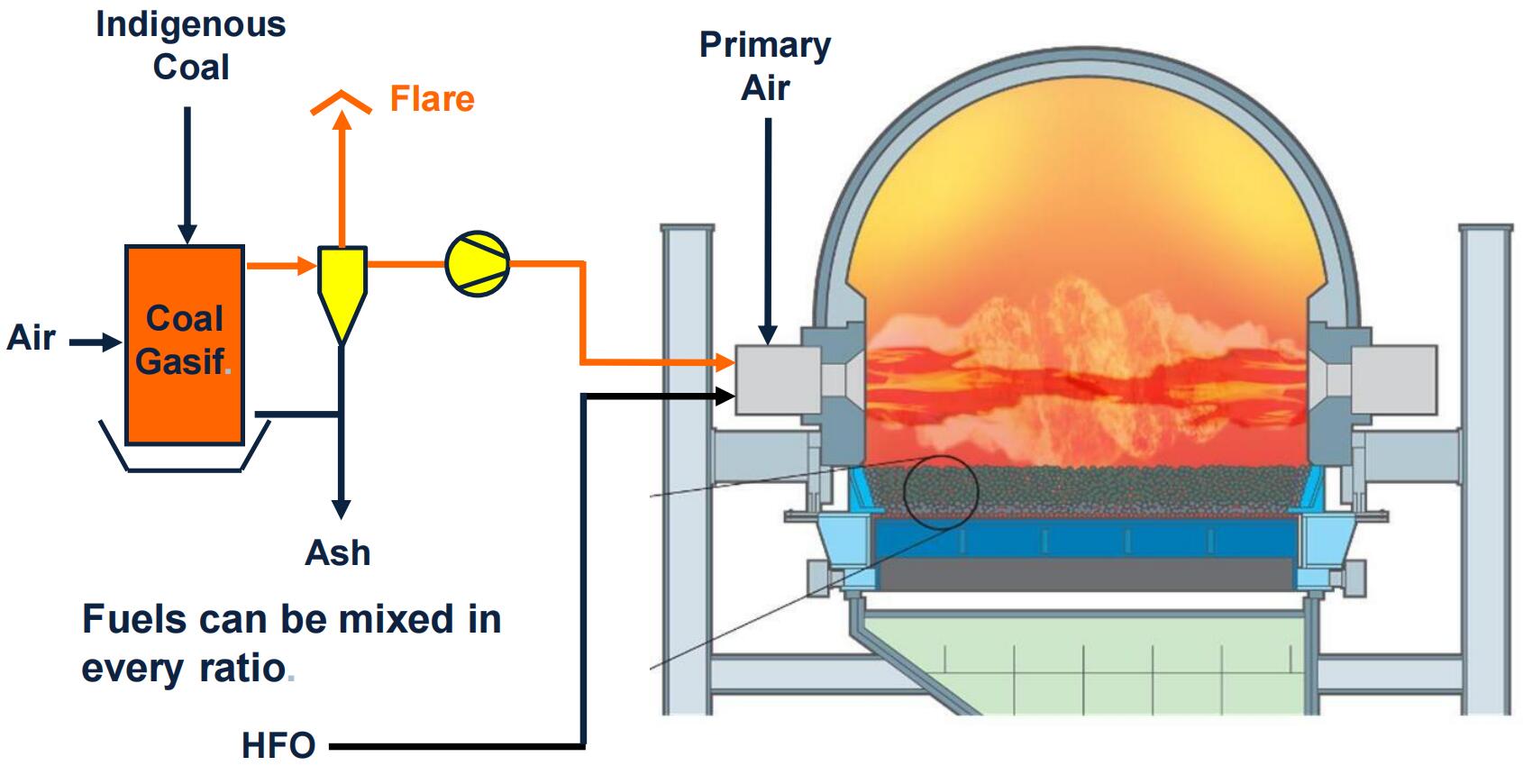

- Simultaneous multi-fuel use

Circular grate pelletizing plants

0.5 – 2.5 Mt/year

pelletizing plants

- Compact plant design

- Proven and reliable equipment

- High compression strength

- Good reducibility of briquettes

Cold briquetting plants

0.05 – 1 Mt/y

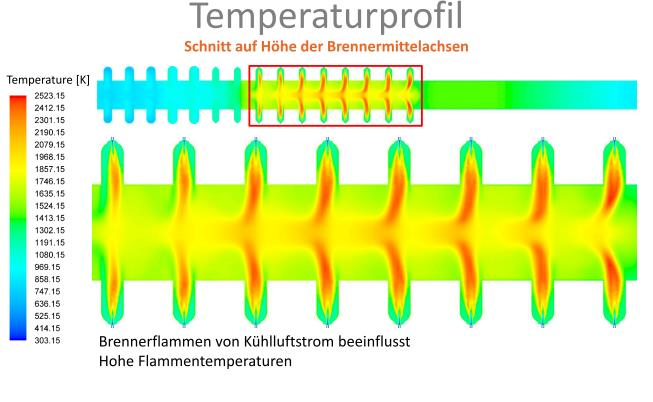

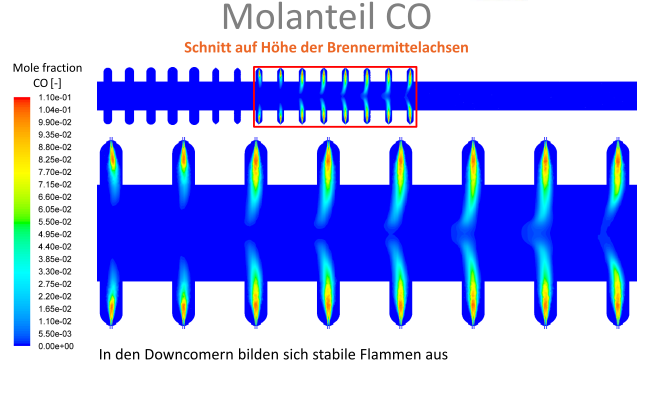

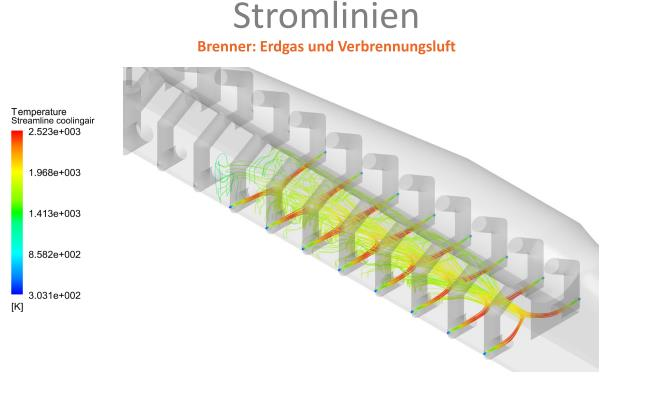

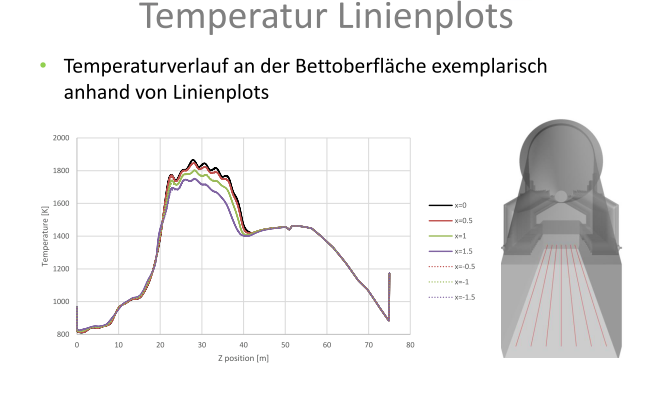

- Advanced process simulation

- OPEX reduction

- Combination with eco solutions

- Utilization of steel works wastes

Advanced Pelletizing Technologies

Plant Design Optimization – Results, Findings

Technical Challenges During Engineering

Development of Feeding Area

By speed variation of reciprocating conveyor more green pellets will be charged on outside than on inside in order to achieve level pellet surface.

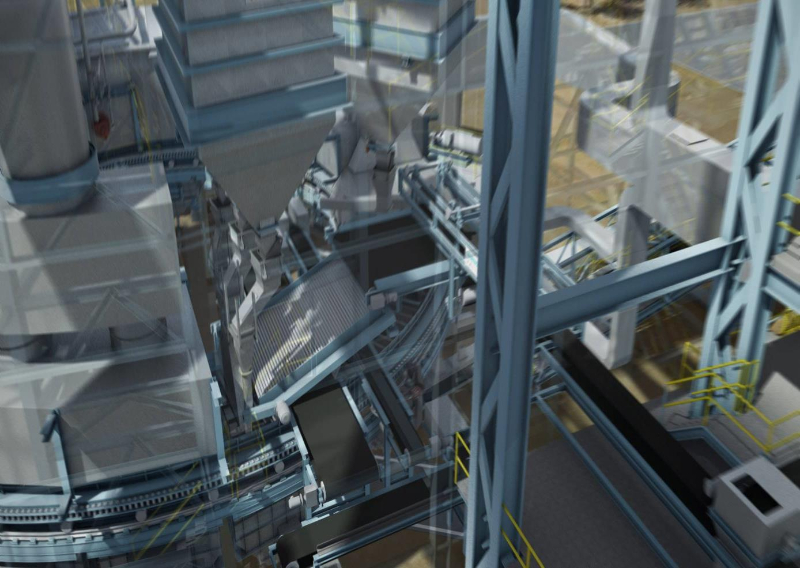

Benefits of a CPT Plant

Compact plant layout, low building profile, short process air ducts, standardized equipment.

Low OPEX due to use of various energy sources: e.g. Coal Gas, PCI, COREX / FINEX Gas, Coke Oven Gas, etc.

Environmental compatibility: 100% recycling of by-products, processing of in-plant waste materials

- Combination with MEROS Technology for Desulphurization of Waste Gas (Hydrated Lime or Bicarbonate based)

- Active Carbon Addition for Removal of Heavy Metals in Waste Gas

- Reduction of NOx by Ultra-Low-NOx Burner Technology or Selective Catalytic Removal

- Re-utilization of approx. 10 % of Steel Work Waste Materials in the Pelletizing Process

- Re-use of Pelletizing Plant Discharge Materials in the Pelletizing Process by Regrinding